Mejoramos tus procesos productivos con nuestras soluciones de inspección avanzada y automatización inteligente.

Problemas identificables. Soluciones comprensibles. Resultados medibles.

CONTÁCTANOS

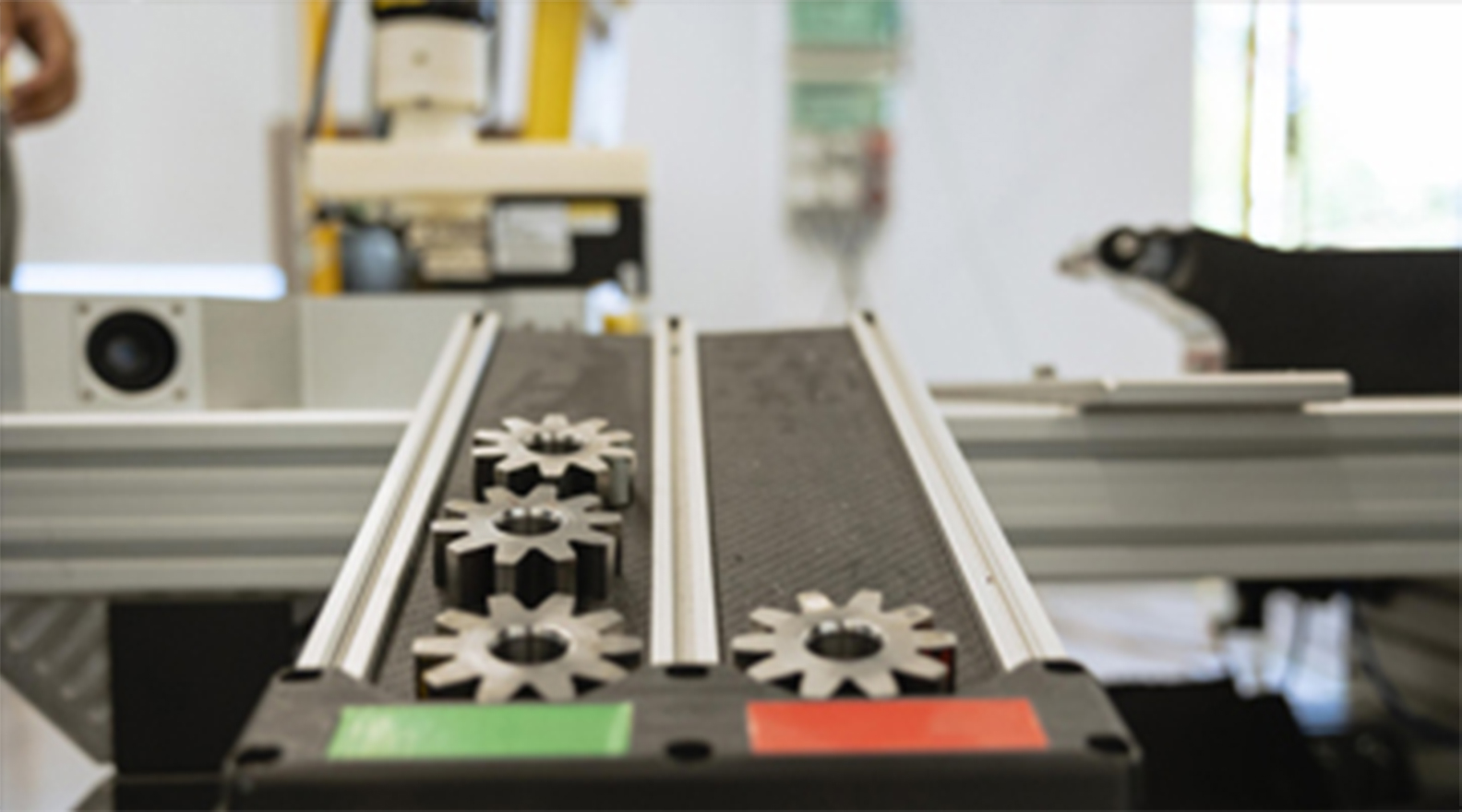

SOLUCIONES DE INSPECCIÓN NO DESTRUCTIVAS

Descubre cómo nuestros equipos NDT pueden reducir el coste y tiempo de la inspección de procesos de tus piezas metálicas.

TECNOLOGÍA

SOLUCIONES DE AUTOMATIZACIÓN INTELIGENTE

Te explicamos cómo reducir tus ineficiencias actuando en tiempo real en función de los datos extraídos de tus máquinas productivas.