A system for the characterization of residual stresses in the steel industry

2023-03-14

2023-03-14 This solution will reduce up to 560 tCO2/year per line

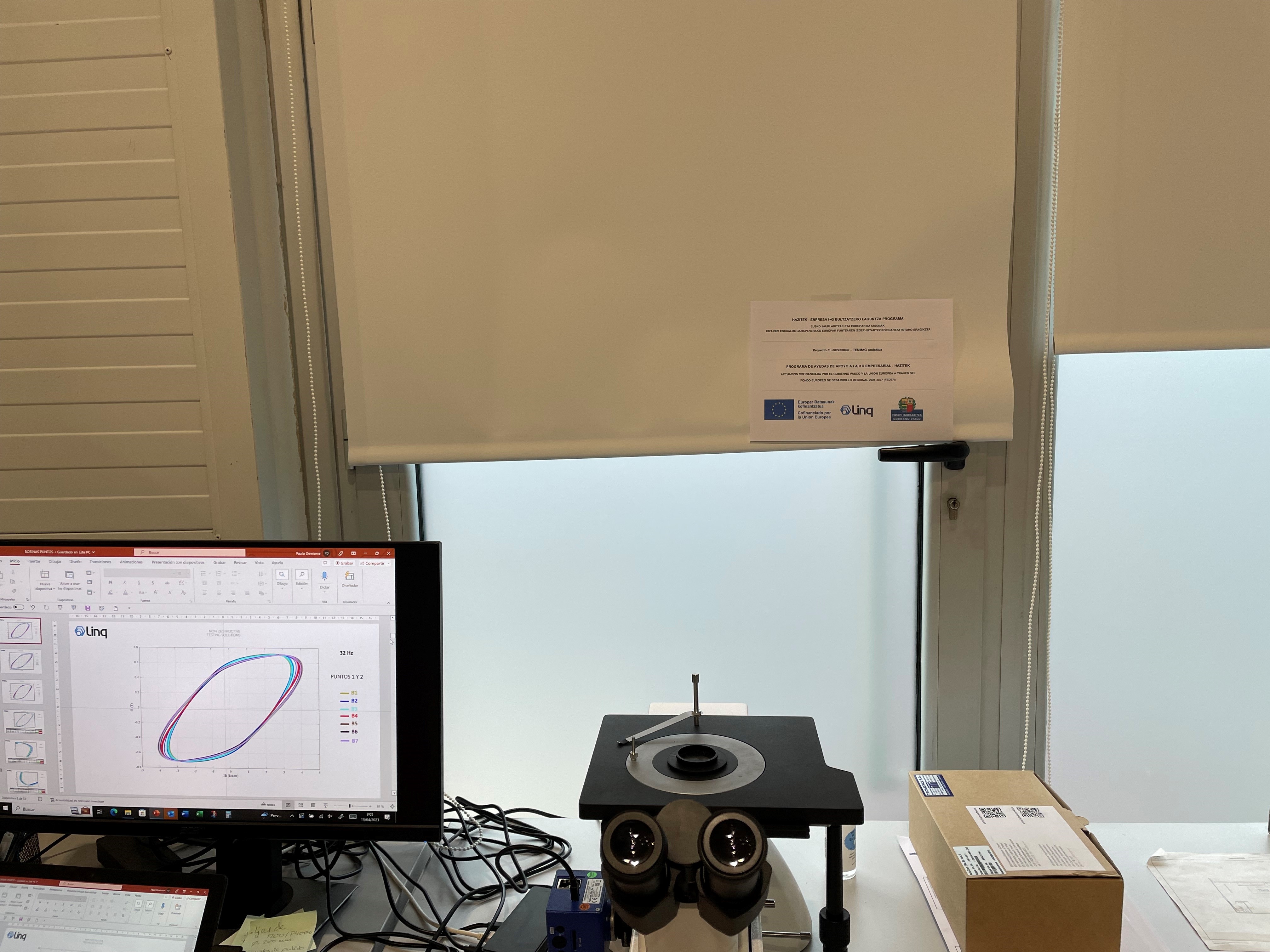

LINQ continues to expand its range of advanced inspection solutions for industry.

In this case, and together with its partners CEIT and SIDENOR, LINQ is developing a system for the characterization of residual stresses in turned steel bars. This is a research project with which LINQ will develop a preliminary prototype of a non-destructive inspection system. The ultimate goal of this line of research is the development of an integrated in-line equipment and will inspect 100% of the bar production in the steel industry.

This project will provide environmental improvements in the steelmaking process, as the stress relieving treatment will be eliminated and the tempering treatment will be reduced by 50%. It is estimated that this will result in a reduction of 562 tCO2/year.

In addition, this solution will allow an increase in productivity and a reduction in the number of rejects due to residual stresses in the rebar production lines.

This technology has been developed together with the Ceit research center, a member of BRTA, within the framework of the TENMAG project, which has been financed by the Basque Government"s Hazitek program for industrial research or experimental development projects.